This article is published as a part of a partnership with Future Food Asia. Iamus is one of the 10 finalists of the US$100,000 Future Food Asia (FFA) 2021 Award to be hosted from June 7-11.

Over the past few years, robots have found a home in the agriculture industry. Their inclusion comes as no surprise as they manage time-consuming and repetitive tasks on the farm. They may not fill the shoes of our perception built on fan favourites such as R2D2 in Star Wars, but robots are making food production more efficient.

The poultry industry is no different, and robots in the coop are helping boost food security, improve animal health and welfare as well as contribute to better labour conditions and farm profits. But can these robots go from task based work to providing predictive insights?

From Filipino small-holders to Irish large-scale processors

Six years ago Shane Kiernan cofounded a business in the Philippines that provides outsourced manpower solutions to the poultry industry – from cleaning poultry sheds to vaccinating baby chicks they did it all. In the course of this business they observed all the challenges and opportunities in poultry production and were particularly curious to understand the drivers behind the wide degree of variability seen in the performance of poultry growers.

One question stuck with Kiernan: why was it that the same tiny proportion of farmers typically outperformed their cohort despite having older equipment or buildings? Fortunately his curiosity carried him to a conversation with Manor Farm, the largest poultry processor in Ireland.

A series of meetings followed where my curiosity validated farm variability is a US$9 billion annual problem for the poultry industry– an industry where low margins and animal welfare pressures abound.

Globally with over 350,000 poultry sheds raising 60 billion birds annually for protein consumption the market was massive but what was the solution to the challenges?

Gallus: A chicken’s best friend

With investment from the family behind Manor Farm and others involved in animal feed milling, Kiernan started Iamus in 2018. Since then Iamus have developed their “Gallus” solution.

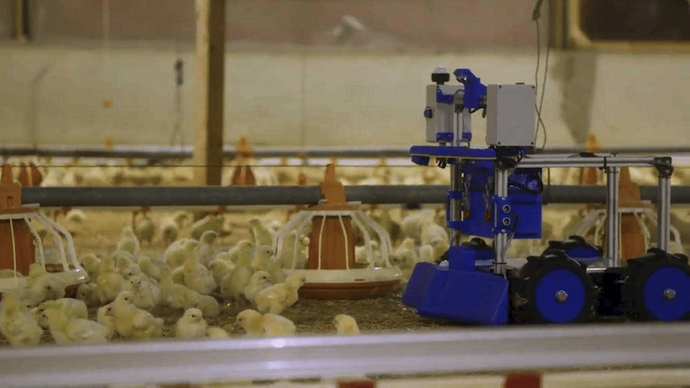

An integrated solution that acquires proprietary data from a mesh of static sensors and an autonomous robot that results in predictive recommendations to the customer that lead to improved margins and better animal welfare outcomes.

This year the team is undertaking extensive customer validation trials in Ireland and Thailand.

The company has invested their time and capital on building the hardware and software components of their. Last year they developed a machine vision capability in their robot. Up to this point our robot relied on non-visual sensors to navigate the poultry shed environment and detect the birds.

“There was a further benefit to machine vision – we could see the birds! In fact we could do more than just see the birds, we could categorise them based on established animal welfare indicators. The possible outcomes that arise from this capability was huge and is our biggest achievement to date allowing us to provide predictive interventions that create enormous value for our customers.” said Kiernan.

Tackling welfare and wastage

The mission at Iamus is to minimise waste in poultry through real-time animal welfare solutions. Gallus aims to change production outcomes by offering predictive insight to poultry producers so they can make necessary and timely interventions that lead to improved margins and better animal welfare outcomes.

Both in Asia and Europe, the robot solution is in great demand, yet they remain constrained by capital and resources to install Gallus. “The Future Food Asia Award Finals is a tremendous opportunity for us to spread our message, share our vision, engage new stakeholders and hopefully make the world a better place” says Kiernan.

Poultry, specifically chicken, is an already efficient source of protein that is the choice of billons of people around the world. Yet wasted opportunities to further optimise production interventions are missed that negatively impact on the carbon footprint and bottom of the line.

–

Editor’s note: e27 aims to foster thought leadership by publishing contributions from the community. This season we are seeking op-eds, analysis and articles on food tech and sustainability. Share your opinion and earn a byline by submitting a post.

Join our e27 Telegram group, FB community or like the e27 Facebook page

The post How Iamus’ machine vision robot Gallus is optimising the poultry industry appeared first on e27.